Views: 181 Author: Site Editor Publish Time: 2024-03-21 Origin: Site

1.Introduction

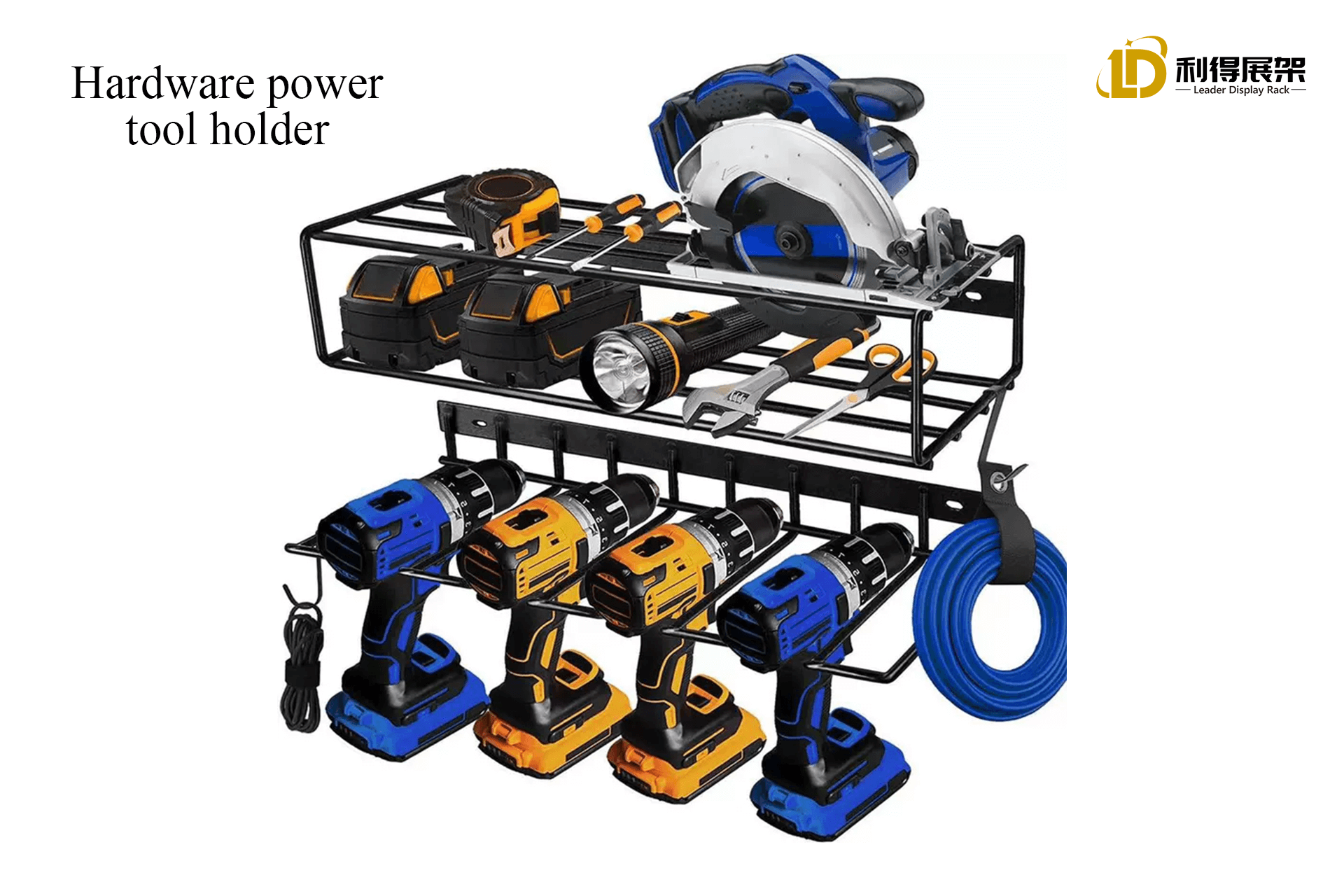

2.Hardware power tool rack design features

3.Work space planning

4.Tool classification and sorting

5.Workflow optimization

6.Ease of use for work

7.Safety and reliability considerations

8.Conclusion

In today's fast-paced work environments, optimizing workspace has become increasingly crucial for enhancing productivity and efficiency. A well-organized workspace not only streamlines workflow but also contributes to a safer and more conducive work environment. Among the various tools and equipment used in different industries, power tools and hardware play a significant role in completing tasks efficiently. However, without proper organization and storage solutions, these tools can clutter the workspace and impede productivity. This is where the importance of specialized storage solutions like hardware and power tool racks comes into play. These racks are specifically designed to efficiently organize and store a variety of power tools and hardware, thereby maximizing workspace utilization and facilitating smooth operations. In this article, we will delve into the significance of optimizing workspace and explore how hardware and power tool racks contribute to improving work efficiency and organizing workspaces effectively.

Towel display rack

Hardware and power tool racks are designed with several key features aimed at providing efficient storage solutions while optimizing workspace organization. One of the primary design aspects is the structure of the rack itself. These racks typically feature sturdy frames constructed from durable materials such as steel or aluminum. The robust frame ensures stability and strength to withstand the weight of various power tools and hardware items.

In addition to the frame, hardware and power tool racks often incorporate adjustable shelves or compartments. This adjustable feature allows users to customize the rack according to the size and shape of different tools and hardware items, maximizing storage capacity and versatility. Some racks may also include dividers or bins within each compartment to further organize smaller items and prevent clutter.

Another important design aspect is the overall size and dimensions of the rack. Hardware and power tool racks come in various sizes to accommodate different workspace layouts and storage needs. Some racks are designed to be compact and space-saving, ideal for smaller workshops or storage areas, while others are larger and more robust, suitable for industrial settings or larger workspaces.

Furthermore, many hardware and power tool racks feature mobility options such as casters or wheels. This mobility allows users to easily move the rack around the workspace as needed, providing flexibility and convenience. Some racks may also include locking mechanisms on the casters to secure the rack in place when stationary, ensuring stability during use.

Overall, the design features of hardware and power tool racks are tailored to provide efficient storage solutions, maximize workspace organization, and enhance user convenience and flexibility.

When it comes to optimizing the layout of hardware and power tool racks within a workspace, careful consideration of the space's size and layout is essential. One of the primary factors to consider is the available floor space and the overall dimensions of the workspace. In smaller workshops or storage areas, it may be necessary to prioritize vertical storage solutions to maximize floor space utilization. This could involve installing tall, freestanding racks or wall-mounted shelving units to store tools and hardware items efficiently without occupying valuable floor space.

Additionally, the layout of the workspace itself plays a crucial role in determining the placement of hardware and power tool racks. It's essential to identify high-traffic areas where easy access to tools and equipment is required and strategically position the racks accordingly. For example, placing racks near workbenches or assembly stations can streamline workflow and minimize unnecessary movement between work areas.

Furthermore, consider the workflow and operational processes within the workspace when planning the layout of hardware and power tool racks. Identify the most frequently used tools and equipment and ensure that they are easily accessible and conveniently located to facilitate efficient work processes. This may involve clustering related tools together or organizing them based on their frequency of use to optimize workflow efficiency.

Another consideration is the ergonomic aspect of tool rack placement. Ensure that the racks are positioned at comfortable working heights to prevent strain or injury during tool retrieval and usage. Adjust shelf heights and rack placement accordingly to accommodate the needs of different users and ensure ergonomic accessibility for all individuals working within the space.

By carefully assessing the size, layout, workflow, and ergonomic requirements of the workspace, it is possible to develop a well-organized and efficient layout for hardware and power tool racks. Strategic placement of racks based on these considerations can help maximize productivity, streamline workflow, and create a safer and more ergonomic work environment.

When organizing hardware and power tools on racks, it is essential to categorize and arrange them based on their types and intended uses. This systematic approach not only facilitates efficient retrieval of tools but also enhances workflow and productivity within the workspace.

One common method of categorization is grouping tools by type or category. For example, hand tools such as screwdrivers, wrenches, and pliers can be grouped together on designated shelves or sections of the tool rack. Similarly, power tools such as drills, saws, and sanders can be organized in separate areas to ensure easy access and retrieval.

Furthermore, consider organizing tools based on their usage frequency. Tools that are frequently used in everyday tasks should be positioned in easily accessible locations within arm's reach, while those used less frequently can be stored in less accessible areas or higher shelves. This arrangement minimizes clutter and streamlines workflow by prioritizing access to commonly used tools.

Another consideration is organizing tools based on their size and weight. Heavier or bulkier tools may require sturdier shelves or dedicated storage spaces to ensure safe and secure placement. Additionally, larger tools such as power saws or drills may benefit from adjustable or customizable rack configurations to accommodate their dimensions effectively.

Additionally, consider the specific needs and preferences of users when organizing tools on racks. Group tools together in a logical and intuitive manner that aligns with users' workflows and tasks. This may involve customizing the layout of the tool rack to match the workflow patterns of individual users or work teams, ensuring that tools are conveniently located and easily accessible during various tasks.

By categorizing tools based on type, usage frequency, size, and user preferences, it is possible to create a well-organized and efficient storage system on hardware and power tool racks. This systematic approach not only enhances the accessibility and usability of tools but also contributes to a more organized and productive workspace environment.

Efficiency in a workshop or workspace heavily relies on the seamless flow of tasks and accessibility to tools. By optimizing the layout of hardware and power tool racks, it is possible to significantly enhance workflow efficiency and smoothness.

One key aspect of optimizing tool rack layout is strategic placement. Tools that are frequently used together or in sequential tasks should be positioned adjacent to each other to minimize unnecessary movement and streamline workflow. For example, if drilling and screwing tasks are often performed consecutively, it makes sense to place the drill and screwdriver racks in close proximity to each other for quick and easy access.

Moreover, consider the workflow patterns of users when arranging tool racks. Analyze the sequence of tasks performed and the natural flow of movement within the workspace. By aligning the layout of tool racks with these workflow patterns, it becomes easier for users to navigate the workspace and access the tools they need without interruption.

Another strategy for optimizing tool rack layout is to prioritize accessibility. Tools that are used more frequently or are essential for critical tasks should be placed within easy reach, preferably at eye level or on lower shelves. This ensures quick access to commonly used tools, reducing downtime and increasing productivity.

Furthermore, consider implementing visual cues or labeling systems to further enhance the efficiency of tool rack layout. Clearly labeling shelves or sections of the rack with the names or images of the tools they contain can help users quickly locate the tools they need, especially in fast-paced or high-pressure work environments.

Additionally, regularly review and adjust the layout of tool racks based on evolving workflow requirements and feedback from users. As work processes change or new tools are introduced, adapt the layout of tool racks accordingly to maintain optimal efficiency and usability.

By strategically placing tools, aligning the layout with workflow patterns, prioritizing accessibility, and utilizing visual cues, it is possible to optimize the layout of hardware and power tool racks to enhance workflow efficiency and smoothness in the workspace. This results in improved productivity, reduced downtime, and a more streamlined work environment overall.

Efficient access to tools is essential for maximizing productivity and streamlining work processes in any workshop or workspace. When designing hardware and power tool racks, several factors should be considered to ensure tools are easily accessible and usable, thus improving overall work efficiency.

Firstly, the design of the tool racks should prioritize accessibility. This involves organizing tools in a logical manner and ensuring they are readily visible and within easy reach. Tools that are used frequently or are essential for specific tasks should be positioned prominently and at ergonomic heights to minimize reaching or bending.

Moreover, the layout of the tool racks should be intuitive, with tools arranged in a manner that aligns with common workflow patterns. For example, tools used in sequence or together for certain tasks should be grouped and stored close to each other to minimize unnecessary movement and optimize workflow efficiency.

Additionally, consider the ergonomics of tool storage. Design tool racks with adjustable shelves or compartments to accommodate tools of various sizes and shapes effectively. This ensures that each tool has its designated storage space, preventing clutter and making it easier to locate and retrieve specific tools when needed.

Furthermore, incorporate features such as tool hooks, holders, or magnetic strips to securely store tools in place and prevent them from falling or getting misplaced. These features not only contribute to a tidy and organized workspace but also facilitate quick and effortless tool retrieval, thus enhancing work efficiency.

Another aspect to consider when designing tool racks is versatility. Design racks that can accommodate a diverse range of tools, including hardware and power tools of different types and sizes. This ensures that the tool storage solution remains flexible and adaptable to changing work requirements and tool inventories over time.

Lastly, integrate visual cues or labeling systems into the design of the tool racks to aid tool identification and retrieval. Clearly labeling shelves or compartments with the names or images of the tools they contain can help users quickly locate the tools they need, further improving efficiency and reducing downtime.

Designing hardware and power tool racks with a focus on accessibility, intuitive layout, ergonomic storage, versatility, and visual cues can greatly enhance work efficiency by ensuring tools are easily accessible and usable in the workspace. This results in smoother workflow processes, increased productivity, and a more organized and efficient work environment overall.

When designing the layout of hardware and power tool racks, safety considerations should be paramount to create a workspace that is secure and reliable for users.

One crucial aspect of safety in rack layout design is stability. Ensure that the racks are securely anchored to the floor or wall to prevent tipping or collapse, especially when loaded with heavy tools or equipment. Additionally, consider the weight capacity of the racks and avoid overloading them beyond their recommended limits to maintain stability and prevent accidents.

Another safety consideration is accessibility. Ensure that tools are stored and arranged in a way that minimizes the risk of accidents or injuries during retrieval. Avoid placing heavy or sharp tools at heights where they could fall and cause harm, and ensure that all tools are easily reachable without the need for excessive stretching or bending.

Furthermore, implement safety features such as guardrails or protective barriers around the racks to prevent accidental contact with sharp or hazardous tools. Consider incorporating locking mechanisms or security measures to prevent unauthorized access to potentially dangerous equipment, particularly in shared or public workspaces.

Additionally, ensure that the layout of tool racks allows for clear and unobstructed pathways within the workspace to facilitate safe movement and navigation. Remove any obstacles or clutter that could pose tripping hazards and maintain adequate lighting to ensure visibility, especially in dimly lit areas.

Regular maintenance and inspections of tool racks are also essential for ensuring safety in the workspace. Routinely check for signs of wear, damage, or instability in the racks, and promptly repair or replace any compromised components to prevent accidents.

By prioritizing safety in the layout of hardware and power tool racks, it is possible to create a workspace that promotes a secure and reliable environment for users, minimizing the risk of accidents or injuries and ensuring optimal productivity and efficiency.

In summary, the importance of hardware and power tool racks in optimizing workspace efficiency cannot be overstated. A well-designed layout and arrangement of these racks play a crucial role in enhancing productivity and improving the overall work experience.

By strategically planning the placement of hardware and power tool racks, it becomes possible to create a workspace that is organized, efficient, and conducive to seamless workflow. Properly positioned racks allow for easy access to tools and equipment, minimizing the time spent searching for items and maximizing the time spent on productive tasks.

Moreover, a thoughtfully laid out rack system ensures that tools are stored safely and securely, reducing the risk of accidents or injuries in the workplace. Safety considerations, such as stability, accessibility, and the implementation of protective measures, contribute to creating a secure environment for users to operate in.

Additionally, a well-organized workspace promotes a sense of professionalism and pride in workmanship, enhancing morale and motivation among employees. It fosters a positive work culture where individuals feel empowered to perform their best and collaborate effectively with their colleagues.

Overall, the careful design and arrangement of hardware and power tool racks not only optimize workspace efficiency but also contribute to a more enjoyable and fulfilling work experience. By prioritizing these aspects, businesses can create a productive and safe environment that supports their goals and objectives.