Views: 147 Author: Site Editor Publish Time: 2024-06-17 Origin: Site

1.Introduction

2.Design concept of aluminum strip storage display stand

3.Manufacturing technology of aluminum strip storage display stand

4.Quality control and testing

5.Detail determines quality

6.Case study

7.Conclusion

In modern industry and families, aluminum strip storage display stands have gradually become an essential storage and display tool because of their lightweight, durable and beautiful characteristics. Whether it is in the workshop for tool storage, material arrangement, or in the home for item display, space optimization, aluminum strip storage display rack plays an important role. It not only helps users rationally use space, improve the efficiency of item management, but also improves the overall visual effect of the environment through beautiful design.

The quality of aluminum storage display rack is not only reflected in its material and function, but more importantly, the control of details in the design and manufacturing process. An excellent display shelf must be perfected in the details of the design, from material selection, processing to assembly, each link needs to be strictly controlled to ensure the quality of the final product and the use experience. Therefore, details determine quality, which is particularly important in the design and manufacture of aluminum strip storage display stands. This article will explore how these details are reflected in the design and manufacturing process, and show how the aluminum strip storage display rack achieves its functional and aesthetic value in practical applications through specific cases.

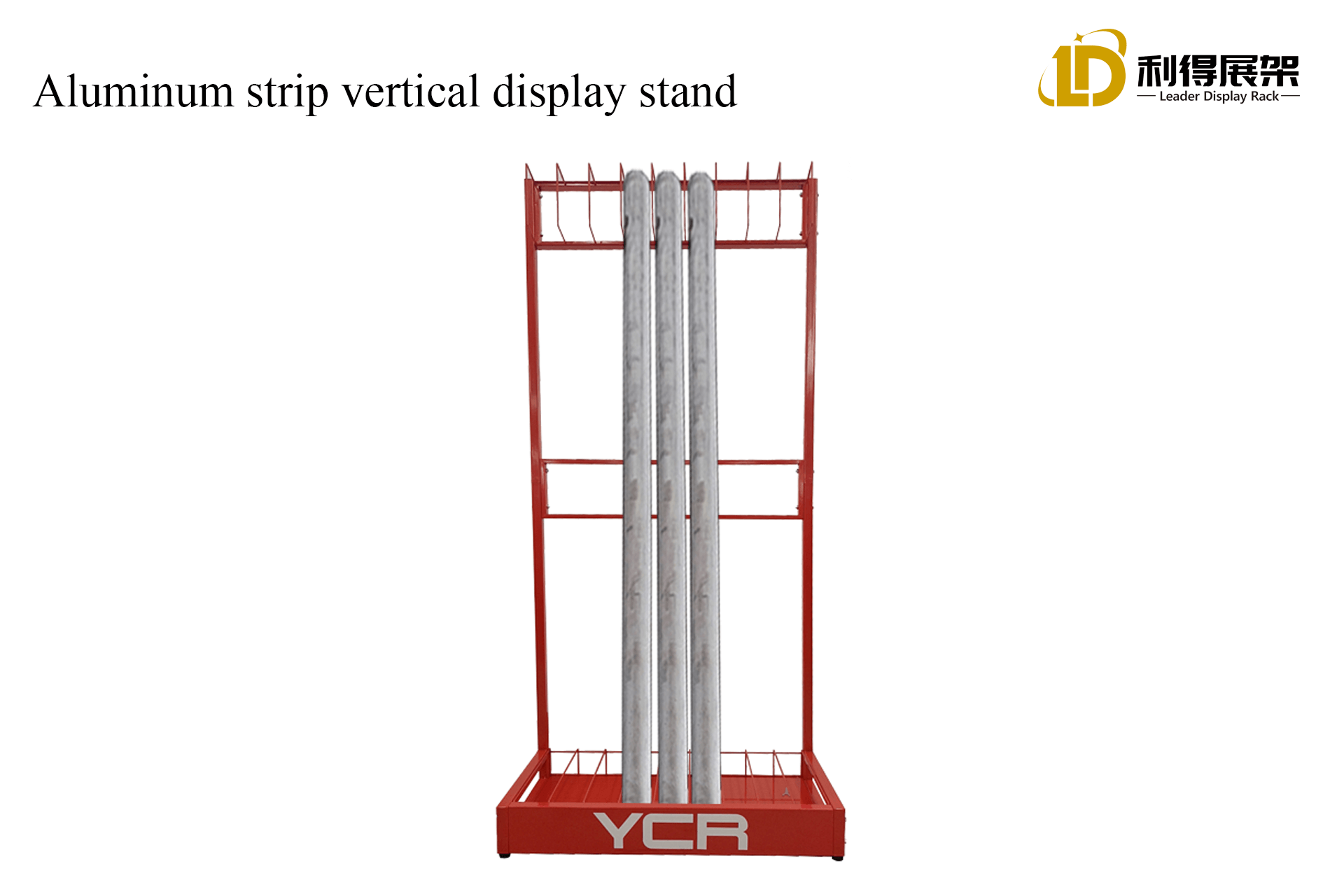

Aluminum rod storage display rack

Aluminum is an ideal choice for display stand manufacturing due to its superior characteristics such as light weight, corrosion resistance and high strength. The low density of aluminum makes the display stand lightweight and easy to handle and install, which greatly facilitates the use of users. At the same time, aluminum has good oxidation resistance and corrosion resistance, is not easy to rust, and can maintain a good condition even in a humid environment, extending the service life of the display shelf. In addition, the high strength properties of aluminum enable it to remain stable and safe while carrying heavy loads, which makes aluminum the preferred material for manufacturing high-quality display shelves.

The application of different aluminum alloy materials in the manufacture of display stands has its own characteristics. For example, 6061 aluminum alloy, with its excellent mechanical properties and good processability, is widely used in the manufacture of display stands requiring high strength and high corrosion resistance. Because of its good corrosion resistance and moderate strength, 5052 aluminum alloy is often used for display stands with high durability requirements. The selection of different aluminum alloy materials can be customized according to the specific needs of the display rack, so as to meet the requirements of various application scenarios.

The cutting, forming and surface treatment process of aluminum is the key link in the manufacturing process of display stand. The cutting process requires high precision to ensure the accurate size of each component of the display stand and the smooth assembly. The molding process needs to ensure that the aluminum will not be deformed or cracked during the processing to ensure the structural integrity and beauty of the display frame. Surface treatment processes, such as anodizing and electrophoretic coating, can not only enhance the corrosion resistance of aluminum, but also give the display rack rich color and texture, and enhance the overall aesthetic value of the product. The application of precision machining technology in these processes directly determines the quality and service life of the display stand.

The connection modes of the display stand mainly include welding and bolt connection. The welding technology can realize the seamless connection of the display rack components, making its structure more stable and durable. However, the welding process is demanding, and it is necessary to ensure the strength and beauty of the weld. The bolted connection method has the advantages of convenient installation and disassembly, especially suitable for display stands that need to be moved or adjusted frequently. No matter which connection method is used, it is necessary to pay attention to the details of the assembly process to ensure the stability and durability of the display shelf, so as to meet the actual needs of users.

Through the introduction of the superior characteristics of aluminum, the analysis of the processing technology and the discussion of the connection mode, it can be seen that the details determine the quality of the aluminum strip storage display rack. Only by paying attention to every detail in the design and manufacturing process can we produce high-quality display shelves that are both beautiful and practical and meet the diversified needs of users.

Aluminum has been widely used in the manufacture of display stands because of its superior characteristics. First of all, the light characteristics of aluminum make the display frame more convenient in the installation and movement process, reducing the burden of the operator. Secondly, the corrosion resistance of aluminum is excellent, which can effectively resist the erosion of moisture and chemical substances in the environment, and ensure that the display shelf is not easy to rust for a long time. In addition, aluminum has high strength and can withstand large weight and pressure, ensuring that the display rack is stable and reliable during use.

The application of different aluminum alloy materials in the manufacture of display stands has its own characteristics. For example, 6061 aluminum alloy is often used for display stands with high strength requirements due to its excellent mechanical properties and good machinability. 5052 aluminum alloy, due to its excellent corrosion resistance and moderate strength, is suitable for display stands with high durability requirements. The diversity of these aluminum alloy materials enables the display rack to be customized according to different use environments and needs to meet the requirements of various application scenarios.

In the manufacturing process of the display stand, the cutting, forming and surface treatment process of aluminum is the key link. The cutting process requires high precision to ensure the accuracy of the dimensions of each component, thus ensuring the smooth assembly of the display rack. The molding process requires that the aluminum will not be deformed or cracked during the processing to ensure the structural integrity and beauty of the display frame. Surface treatment processes, such as anodizing and electrophoretic coating, can not only improve the corrosion resistance of aluminum, but also give the display shelf rich color and texture, enhancing its aesthetic value. The application of precision machining technology in these processes directly affects the quality and service life of the display stand, ensuring that the final product can meet the requirements of high standards.

The connection modes of the display stand mainly include welding and bolt connection. Welding technology can achieve seamless connection of display rack components, making its structure more stable and durable. However, the welding process is demanding, and it is necessary to ensure the strength and beauty of the weld. The bolted connection method has the advantages of convenient installation and disassembly, especially suitable for display stands that need to be moved or adjusted frequently. No matter which connection method is used, it is necessary to pay attention to the details of the assembly process to ensure the stability and durability of the display shelf, so as to meet the actual needs of users.

Through the introduction of the superior characteristics of aluminum, the analysis of the processing technology and the discussion of the connection mode, it can be seen that the details determine the quality of the aluminum strip storage display rack. Only by paying attention to every detail in the design and manufacturing process can we produce high-quality display shelves that are both beautiful and practical and meet the diversified needs of users.

In the manufacturing process of aluminum strip storage display stand, the quality inspection standards and methods of each link are the key to ensure product quality. First of all, in the raw material procurement stage, we strictly in accordance with national and industry standards, the chemical composition, mechanical properties and dimensional accuracy of aluminum alloy materials are tested to ensure that the materials used meet the design requirements and use standards. After the material enters the factory, sample testing is also carried out to verify the quality stability of the supplier.

Cutting and forming process is an important link in the manufacture of display stand. In the cutting process, we use high-precision CNC cutting equipment, and strictly monitor the cutting accuracy to ensure the accuracy of the cutting size. During the molding process, high precision molds and automatic molding equipment are used to ensure that the parts after forming have good dimensional stability and surface quality. Each batch of molded parts is sampled to check their dimensions, tolerances and surface finish to ensure that each part meets the design requirements.

Surface treatment is an important step to improve the corrosion resistance and beauty of the display stand. After the surface treatment process such as anodic oxidation and electrophoretic coating is completed, we will test the surface treatment effect, including film thickness, adhesion and corrosion resistance. Through special testing equipment, such as film thickness meter, adhesion tester and salt spray test chamber, to ensure that the surface treatment layer is uniform, firmly attached, and has good corrosion resistance.

In the assembly of the display stand, we adopt strict process control and quality inspection standards. Non-destructive testing, such as ultrasonic inspection and X-ray inspection, is carried out on the welding parts to ensure that there are no cracks, pores and non-fusion defects in the welding. The fastening force of the bolt connection is tested by a torque wrench to ensure that the connection is firm and reliable. After the assembly is complete, the display stand is inspected for dimensions, flatness and verticality in all aspects to ensure the structural stability and aesthetics of the final product.

Before leaving the factory, we carry out strict quality inspection on each piece of display stand. The first is the appearance inspection, to ensure that the surface is smooth, consistent color, no obvious scratches and defects. The second is the structural inspection, through the measurement tool to check the size, Angle and connection of each component, to ensure that the design drawing requirements. Finally, functional tests, including load-bearing tests and durability tests. In the load-bearing test, we simulate the actual use environment and carry out loading tests on the display frame to ensure that it does not deform or break under the maximum design load. In the durability test, the reliability of the display stand in long-term use is verified through repeated disassembly and use tests.

In the process of use, the display rack often faces the challenges of various environmental conditions. To ensure the service life of our products in different environments, we carry out a series of durability and environmental adaptability tests. Anti-corrosion test is an important content, through the salt spray test, wet heat test, etc., to simulate the use of the display rack in the wet and salt spray environment, evaluate its anti-corrosion performance. Rust testing is mainly for metal components, through coating testing and long-term exposure tests to verify their rust resistance. In addition, wear tests are carried out to evaluate the wear resistance of the surface treatment layer through friction testing machines to simulate wear in daily use.

Through strict quality inspection standards and methods, we ensure that every link of the display stand in the manufacturing process meets the high quality requirements. At the same time, through the strict inspection procedure before the factory and the service life test in a variety of environments, to ensure the durability and reliability of the display rack in actual use, so as to provide users with high-quality products.

In the design process of aluminum strip storage display stand, innovation and detail optimization are the key to enhance product competitiveness and user experience. First, in the design phase, we introduced the modular design concept, so that the display shelf has a high degree of flexibility and scalability. Through the modular design, users can freely combine various parts of the display rack according to actual needs to meet the needs of different scenarios and uses. This innovative design not only improves the functionality of the display stand, but also makes its installation and disassembly easier, greatly improving the user experience.

In terms of detail optimization, we pay special attention to the corner treatment and surface finish of the display stand. The corner of the display frame adopts the arc design, which not only improves the safety, prevents the user from being scratched by the sharp edge during use, but also increases the beauty and feel of the product. On the surface treatment, we use advanced anodizing technology to form a hard protective film on the surface of aluminum, which not only improves wear resistance and corrosion resistance, but also makes the display stand have better texture and gloss. These details not only reflect the high quality of the product, but also enhance the user's trust and satisfaction with the product.

In the manufacturing process, the excellence of every detail is an important means to ensure product quality. First of all, in the aluminum cutting and forming process, we use high-precision CNC equipment to ensure that the size of each component is accurate. The cut aluminum is carefully polished and polished to ensure smooth edges without burrs and improve assembly accuracy and safety. During the molding process, we make sure that the size and shape of each part are perfectly consistent by adjusting the mold and process parameters several times.

In terms of surface treatment, we strictly control every process link to ensure the uniformity and adhesion of the surface treatment layer. Anodic oxidation, electrophoretic coating and other processes are strictly controlled by parameters and quality testing to ensure that the surface treatment effect reaches the best state. Each batch is salt spray tested and adhesion tested to ensure corrosion resistance and the firmness of the surface treatment layer.

In the assembly of the display stand, we pay attention to every detail of fine processing and strict control. Welding parts through non-destructive testing, to ensure that the welding quality without defects; A torque wrench is used to test the fastening force of the bolt connection to ensure a solid and reliable connection. After the assembly is completed, the display shelf also needs to go through a comprehensive size, flatness and verticality inspection to ensure the installation accuracy of each component and the stability of the overall structure.

In addition, we carry out strict quality inspection on each display stand before leaving the factory, including appearance inspection, structural inspection and functional testing. The appearance inspection ensures that there is no scratch and no color difference on the surface, the structural inspection ensures that the dimensions of each component are accurate, and the functional test includes the load-bearing test and the durability test to ensure the stability and durability of the display stand in actual use.

Through innovation and detail optimization in the design, we not only enhance the functionality and aesthetics of the display shelf, but also greatly improve the user experience. In the manufacturing process, we ensure the high quality and reliability of the display stand through the excellence and strict control of every detail. It is these attention to detail and insistence on quality that make our products highly competitive in the market and win wide recognition from users.

In the design and manufacturing process of aluminum strip storage display stands, we have accumulated many successful cases, each case shows our excellence in design and manufacturing details, and how to improve product quality through these details.

The first example is the aluminum strip storage display rack we designed for a large supermarket. This display shelf adopts a modular design, which can flexibly adjust the layout of the display shelf according to the size and quantity of different products. Through the use of high-strength aluminum alloy material, not only to ensure the light display frame, but also has a strong load-bearing capacity. We use high-precision CNC equipment in the cutting and forming process to ensure the exact size of every component. The surface treatment adopts anodic oxidation technology, so that the display shelf not only has good wear resistance and corrosion resistance, but also increases the beauty. Customer feedback This display shelf is not only convenient to install, but also performs well in the process of use, which greatly improves the display effect of goods and the overall image of the supermarket.

The second case is an aluminum strip storage display for a high-end home goods store. This display shelf emphasizes the combination of beauty and practicality, using circular corner design and smooth surface treatment, making it look stylish and atmospheric, safe and reliable. We have carried out non-destructive testing on the welding parts to ensure that every solder joint is strong and free of defects. During the assembly process, the fastening force of the bolt connection part is tested by a torque wrench to ensure that the connection is firm and reliable. Customer feedback This display shelf not only improves the grade of the store, but also receives unanimous praise from customers, who think that the display shelf is beautiful and practical, which greatly improves the shopping experience.

The third case is an aluminum strip storage display rack designed for an industrial equipment company. This display requires extremely high durability and load-bearing capacity, so we chose high-strength industrial aluminum alloy, and the structural design has been optimized several times. The display shelf adopts a modular design, which can be quickly adjusted and expanded according to different usage requirements. On the surface treatment, we adopted the electrophoretic coating process to further improve the corrosion resistance and wear resistance of the display stand. Customer feedback This display shelf in the use of excellent performance, greatly improve the efficiency of warehousing and management, but also showed a high durability, by the company's internal recognition.

It can be seen from these successful cases that we pay attention to every detail in the design and manufacturing process to ensure high quality products. Fine cutting and forming process, precise welding and assembly process, advanced surface treatment technology, all these provide guarantees for the high quality of products. The customer's high opinion of these display stands is also a testament to the great value brought by our insistence on detail and quality. Detailed design and high-quality manufacturing not only enhance the product experience, but also enhance customer satisfaction and trust, and win us more markets and customers. It is the unremitting efforts on these details that make our display rack products stand out in the competitive market and become the first choice of customers.

In the design and manufacture of aluminum strip storage display stand, the key details directly determine the quality and market competitiveness of the product. From material selection to processing, to structural design and surface treatment, every link must be refined to ensure the excellent performance and user experience of the final product. First of all, the selection of high-quality aluminum alloy materials is the basis for ensuring that the display shelf is lightweight, corrosion resistance and high strength. Different types of aluminum alloy are selected according to demand, which directly affects the load-bearing capacity and service life of the display rack. Secondly, precision cutting, forming and welding processes ensure that each component is dimensional and structurally sound. These details cannot be ignored in the production process and are directly related to the safety and stability of the product. Surface treatment is also key, through anodic oxidation, electrophoretic coating and other advanced technologies, not only to improve the beauty of the display shelf, but also to enhance its corrosion resistance and wear resistance. Finally, strict quality testing and acceptance procedures before leaving the factory are the last gateway to ensure product quality. Various tests, such as durability tests, load-bearing tests, etc., are important means to verify that products meet high standards. In short, the excellent quality of the aluminum storage display rack comes from the careful design and manufacturing of every detail, which not only determines the market competitiveness of the product, but also directly affects the user's purchase decision and long-term satisfaction. Therefore, industry practitioners are encouraged to always pay attention to details in the process of product development and manufacturing, and constantly improve the overall quality and technical level to win wider market recognition and user trust.